ANSI / ASME B16.9 Short Radius Elbow

ASME/ ANSI B16.9 Short Radius Elbow in manufacturer in Mumbai, India, MSS SP-75 BS1640 Stainless Steel Short Radius Elbow Suppliers.

Titanium Short Radius Elbow Short Radius Elbow Material used in our regular production line include various kinds of alloys. Short Radius Bend Elbow are manufactured using quality material such as Hastelloy, Monel, Nickel, Inconel, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 as well as Cupro-Nickel 70/30. These fittings can be made in various deal of Short Radius Elbow Stainless Steel grades such as ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Titanium Short Radius Elbow

What is ASME B16.9 Short Radius Elbow?

The specification for ASME B16.9 Standard covers overall tolerances, ratings, dimensions, testing as well as markings for wrought factory-made butt-welding fittings such as the ASME B16.9 Short Radius Elbow. In our factory, we produce the Short Radius Elbow in various sizes. Our stocklist of ASME B16.9 Short Radius Elbow is available in between the size range NPS ½ inch through 48 inhces (DN 15 through 1200).

Short Radius Elbow Stainless Steel Specification

| Specifications | SME B16.9 Short Radius Elbow |

|---|---|

| SR Bw Elbow size | Seamless Butt Weld Fittings: 1/2″ – 10″ Welded Butt Weld Fittings: 1/2″ – 48″ |

| ASME B16.9 Short Radius Elbow Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| ANSI B16.9 Short Radius Elbow Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| ASME Short Radius Elbow Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Stainless Steel Short Radius Elbow 1.5dType | DN15-DN1200 |

| Connection For Short Radius Weld Elbow | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| 10 Inch Short Radius Elbow Size Range | ½” NB to 24″ NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| 12 Inch Short Radius Elbow Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D,

5D,

6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process for Carbon Steel Short Radius Elbow Pipe Fittings | Push, Press, forge, Cast, etc. |

| 90 Degree Short Radius Pipe Elbow Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills For Short Radius Grooved Elbow | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for Short Radius Elbow Sch 40 |

|

| Application |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Carbon Steel Short Radius Elbow Pipe Fittings Material

ASME B16.9 Short Radius Elbow Types

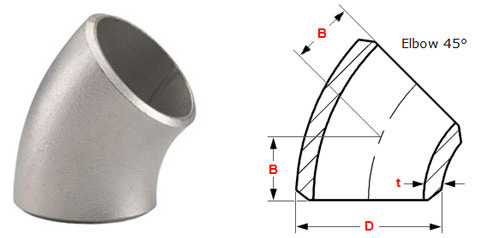

ASME B16.9 Short Radius Elbow Dimensions

| NPS | O.D. D |

45 degrees Short Radius Center-to-End A |

45 degrees 3D Center-to-End A |

| 1/2 | 21.3 | 38 | - |

| 3/4 | 26.7 | 38 | 57 |

| 1 | 33.4 | 38 | 76 |

| 1¼ | 42.2 | 48 | 95 |

| 1½ | 48.3 | 57 | 114 |

| 2 | 60.3 | 76 | 152 |

| 2½ | 73 | 95 | 190 |

| 3 | 88.9 | 114 | 229 |

| 3½ | 101.6 | 133 | 267 |

| 4 | 114.3 | 152 | 305 |

| 5 | 141.3 | 190 | 381 |

| 6 | 168.3 | 229 | 457 |

| 8 | 219.1 | 305 | 610 |

| 10 | 273 | 381 | 762 |

| 12 | 323.8 | 457 | 914 |

| 14 | 355.6 | 533 | 1067 |

| 16 | 406.4 | 610 | 1219 |

| 18 | 457 | 686 | 1372 |

| 20 | 508 | 762 | 1524 |

| 22 | 559 | 838 | 1676 |

| 24 | 610 | 914 | 1829 |

| 26 | 660 | 991 | 1981 |

| 28 | 711 | 1067 | 2134 |

| 30 | 762 | 1143 | 2286 |

| 32 | 813 | 1219 | 2438 |

| 34 | 864 | 1295 | 2591 |

| 36 | 914 | 1372 | 2743 |

| 38 | 965 | 1448 | 2896 |

| 40 | 1016 | 1524 | 3048 |

| 42 | 1067 | 1600 | 3200 |

| 44 | 1118 | 1676 | 3353 |

| 46 | 1168 | 1753 | 3505 |

| 48 | 1219 | 1829 | 3658 |

ASME B16.5 Short Radius 90 Degree Elbow Dimensions

| NPS | O.D. D |

Center-to-End A |

| 1 | 33.4 | 25 |

| 1¼ | 42.2 | 32 |

| 1½ | 48.3 | 38 |

| 2 | 60.3 | 51 |

| 2½ | 73 | 64 |

| 3 | 88.9 | 76 |

| 3½ | 101.6 | 89 |

| 4 | 114.3 | 102 |

| 5 | 141.3 | 127 |

| 6 | 168.3 | 152 |

| 8 | 219.1 | 203 |

| 10 | 273 | 254 |

| 12 | 323.8 | 305 |

| 14 | 355.6 | 356 |

| 16 | 406.4 | 406 |

| 18 | 457 | 457 |

| 20 | 508 | 508 |

| 22 | 559 | 559 |

| 24 | 610 | 610 |

ASME B 16.9 Buttweld 180° Short Radius Elbow Dimensions

| NPS | O.D. D |

180° Short Radius | |

| Center to Center O |

Back to Face K |

||

| 1/2 | 21.3 | - | - |

| 3/4 | 26.7 | - | - |

| 1 | 33.4 | 51 | 41 |

| 1¼ | 42.2 | 64 | 52 |

| 1½ | 48.3 | 76 | 62 |

| 2 | 60.3 | 102 | 81 |

| 2½ | 73 | 127 | 100 |

| 3 | 88.9 | 152 | 121 |

| 3½ | 101.6 | 178 | 140 |

| 4 | 114.3 | 203 | 159 |

| 5 | 141.3 | 254 | 197 |

| 6 | 168.3 | 305 | 237 |

| 8 | 219.1 | 406 | 313 |

| 10 | 273 | 508 | 391 |

| 12 | 323.8 | 610 | 467 |

| 14 | 355.6 | 711 | 533 |

| 16 | 406.4 | 813 | 610 |

| 18 | 457 | 914 | 686 |

| 20 | 508 | 1016 | 762 |

| 22 | 559 | 1118 | 838 |

| 24 | 610 | 1219 | 914 |

Dimensional Tolerances Of ANSI B16.9 Short Radius Elbow

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 180/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Øat Bevel | Inside Øat End | Wall Thicknesst / t1 | Center to End Dim. A-B-C-M | Center to Center Dim.O | Back to Face Dim.K | Align- ment of EndsU |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |