Galvanized Pipe Fittings :

Galvanized pipe fittings are pipe connectors that have been coated with a layer of zinc to protect them from corrosion. This coating enhances the durability and longevity of the fittings, making them suitable for use in various applications, especially in environments where exposure to moisture and corrosive elements is a concern.

Here are some details about galvanized pipe fittings :

Material: Galvanized pipe fittings are typically made from steel. The galvanization process involves applying a protective layer of zinc to the steel surface through a hot-dip or electroplating method.

Corrosion Resistance: The primary purpose of galvanizing is to provide corrosion resistance. The zinc coating acts as a sacrificial layer, corroding before the underlying steel does. This makes galvanized fittings particularly well-suited for outdoor applications and areas prone to moisture.

Types of Fittings: Galvanized pipe fittings come in various types, including elbows, tees, couplings, unions, caps, and more. These fittings serve different purposes in piping systems, such as changing the direction of pipes, connecting pipes of different sizes, or closing off pipe ends.

Threaded or Socket Welded:Galvanized pipe fittings are often available with threaded ends or socket-welded ends. Threaded fittings are screwed onto the pipes, while socket-welded fittings are welded directly to the pipe.

Sizes and Dimensions: Galvanized pipe fittings are manufactured in various sizes to match standard pipe dimensions. The size is typically specified by the nominal pipe size (NPS) or the outside diameter (OD) of the pipes.

Applications: Galvanized pipe fittings are commonly used in plumbing, water distribution, gas lines, and various industrial applications. They are especially popular for outdoor applications where pipes are exposed to the elements.

Standards: Galvanized pipe fittings are manufactured in accordance with industry standards, including specifications from organizations such as ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute).

Galvanized Pipe Fittings It's important to note that while galvanized fittings provide effective corrosion resistance, they may not be suitable for certain applications where the presence of zinc is a concern, such as in some chemical processing or high-temperature environments. In such cases, alternative materials like stainless steel or plastic fittings might be more appropriate.

Galvanized fitting are also referred to as galvanized steel fitting, are divided into two categories hot-dip galvanizing and electro-galvanizing. While hot-dip galvanizing creates a thick layer, with the Galvanised Fittings having a uniform plating, in addition to the advantage of strong adhesion as well as long service life.

Galvanized Pipe Fittings

What Is Galvanised Fittings?

Speaking of the manufacturing process of these fittings, since zinc has been used to plate the surface of the Galv Steel Pipe Fittings, the time initially required for the fittings to either undergo oiling or lacquering their surface has been omitted. Thus the manufacturing process is not only more convenient but is also a cost saving and time efficient one. Lastly, the Gi Tee Fittings do not easily freeze or crack even if they have been exposed to cold weather, which makes these fitting particularly well suited for the cold and freezing environment. Industries like oil and gas as well as petrochemical and petroleum refineries prefer using the Gi Pipe Fittings due to their properties.

Galvanised Pipe Fittings Dimensions

Galvanised Reducing Elbow Dimension

| NPS in millimeter |

A in millimeter |

D in millimeter |

| 20x15 | 34 | 35 |

| 25x20 | 38 | 40 |

| 25x15 | 35 | 39 |

| 32x15 | 37 | 42 |

| 32x20 | 39 | 44 |

| 32x25 | 40 | 44 |

| 40x15 | 38 | 46 |

| 40x20 | 40 | 46 |

| 40x25 | 44 | 47 |

| 40x32 | 49 | 50 |

| 50x15 | 41 | 51 |

| 50x20 | 41 | 51 |

| 50x25 | 46 | 55 |

| 50x32 | 49 | 55 |

| 50x40 | 53 | 57 |

| 65x15 | 46 | 62 |

| 65x20 | 48 | 63 |

| 65x25 | 49 | 63 |

| 65x32 | 54 | 66 |

| 65x40 | 57 | 66 |

| 65x50 | 63 | 69 |

| 80x15 | 47 | 70 |

| 80x20 | 48 | 70 |

| 80x25 | 52 | 71 |

| 80x32 | 57 | 73 |

| 80x40 | 60 | 72 |

| 80x50 | 65 | 75 |

| 80x65 | 73 | 76 |

| 100x15 | 52 | 80 |

| 100x20 | 55 | 82 |

| 100x25 | 56 | 87 |

| 100x32 | 64 | 86 |

| 100x40 | 68 | 89 |

| 100x50 | 74 | 90 |

| 100x65 | 81 | 95 |

| 100x80 | 86 | 96 |

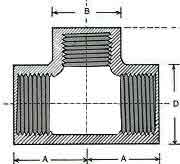

Galvanised Reducing Tee Dimension

| NPS in millimeter |

A in millimeter |

B in millimeter |

C in millimeter |

D in millimeter |

| 20x15 | 33 | 30 | 30 | 30 |

| 25x15 | 33 | 30 | 37 | 42 |

| 25x20 | 35 | 36 | 37 | 42 |

| 32x15 | 36 | 30 | 42 | 51 |

| 32x20 | 37 | 35 | 44 | 51 |

| 32x25 | 40 | 42 | 45 | 51 |

| 40x15 | 38 | 30 | 47 | 58 |

| 40x20 | 40 | 36 | 47 | 58 |

| 40x25 | 43 | 42 | 48 | 58 |

| 40x32 | 47 | 51 | 48 | 58 |

| 50x15 | 38 | 30 | 52 | 71 |

| 50x20 | 41 | 36 | 53 | 71 |

| 50x25 | 45 | 41 | 54 | 71 |

| 50x32 | 45 | 51 | 55 | 71 |

| 50x40 | 52 | 58 | 58 | 71 |

| 65x50 | 62 | 71 | 56 | 88 |

| 80x15 | 50 | 30 | 67 | 100 |

| 80x20 | 51 | 36 | 71 | 100 |

| 80x25 | 51 | 41 | 71 | 100 |

| 80x32 | 56 | 51 | 72 | 100 |

| 80x40 | 58 | 58 | 71 | 100 |

| 80x50 | 64 | 71 | 71 | 100 |

| 80x65 | 72 | 88 | 72 | 100 |

| 100x15 | 52 | 30 | 82 | 126 |

| 100x20 | 53 | 36 | 82 | 126 |

| 100x25 | 57 | 41 | 83 | 126 |

| 100x32 | 62 | 51 | 87 | 126 |

| 100x40 | 65 | 58 | 87 | 126 |

| 100x50 | 72 | 71 | 89 | 126 |

| 100x65 | 78 | 88 | 89 | 126 |

Galvanised Pipe Nipple Dimension

| NPS in millimeter |

A in millimeter |

D in millimeter |

| 15 | 49 | 27 |

| 20 | 54 | 30 |

| 25 | 61 | 38 |

| 32 | 66 | 47 |

| 40 | 71 | 54 |

| 50 | 81 | 67 |

| 65 | 90 | 84 |

| 80 | 99 | 96 |

| 100 | 120 | 123 |

| 150 | 152 | 193 |

Galvanised Union Dimension

| NPS in millimeter |

A in millimeter |

B in millimeter |

D in millimeter |

| 15 | 53 | 26 | 30 |

| 20 | 58 | 55 | 36 |

| 25 | 68 | 64 | 41 |

| 32 | 73 | 75 | 51 |

| 40 | 74 | 84 | 58 |

| 50 | 79 | 95 | 71 |

| 65 | 89 | 113 | 88 |

| 80 | 99 | 131 | 100 |

| 100 | 110 | 153 | 127 |

| 150 | 146 | 223 | 182 |

Industrial Galvanised Pipe Fittings Specification

| Standard Specification : | Galvanised Fittings |

| Rating Pressure: | Pressure Rating Of: 3000 LBS, 6000 LBS, 9000 LBS |

| Check Sizes: | (SMLS UPTO 24”) 1/2” TO 36” (Buttweld 8” TO 36” ) |

| Thickness: | View Our Thickness: Schedule 5S, SCH10, SCH20, SCH10, SCH20, SCH30, SCHTD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160. |

| Standard: | MSS-SP-43 Type A Fittings, MSS-SP-43 Type B Fittings, JIS B2313 Fittings, ANSI B16.9 Fittings, ANSI B16.28 Fittings, JIS B2312 Fittings, MSS-SP-43 Type b Fittings |

| Dimensions Class: | 2000#, 3000#, 6000#, 9000# |

| Application: | Natural Gas Industry Fabrication Industry Chemical Industry Water Pipeline Industry Nuclear Power Plant Oil And Gas Industry |

| Coating Fitting Faces : | Cold and Hot Dip Galvanized, Yellow Transparent, Oil Black Paint, Zinc Plated, Anti-rust Paint |

| Fitting Machining Equipment: | Press machine, electric bevelling machine, Bending machine, Pushing Machine, Sand-blasting machine etc |

Galvanised Steel Fittings Pressure Rating

| Galvanised Fittings Pressure Rating (psig) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (inch) |

Pipe Sch. | OD (inch) |

Wall Thick. (in) |

Temperature (oF) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | |||||||

| Allowable Stress (Pressure Rating) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | |||||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | |||

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | ||||

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | ||||

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | |||

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | ||||

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | ||||

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | |||

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | ||||

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | ||||

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | |||

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | ||||

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | ||||

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | |||

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | ||||

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | ||||

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | |||

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | ||||

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | ||||

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | |||

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | ||||

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | ||||

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | |||

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | ||||

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | ||||

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | |||

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | ||||

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | ||||

Galvanised Plumbing Fittings Size Chart

| Products | Size |

| Galvanised Cups | 1/2'' NB to 14'' NB |

| Galvanised Stub Ends | 1/2'' NB to 14'' NB |

| Galvanised Elbow | 1/2'' NB to 14'' NB |

| Galvanised Reducers | 1'' NB to 14'' NB |

| Galvanised Tees | 1'' NB to 14'' NB |

| Galvanised Socket Weld | Upto 2'' NB |

| Galvanised Nipples | Upto 4'' |

| Galvanised Couplings | Upto 4''NB |